Mark Dopson’s mining waste cleanse

The mining industry is often considered a dirty business. The environmental impact is severe to say the least. But can research mitigate the negative effects? Mark Dopson is investigating precisely this, and generates some electricity while doing it.

“Clouds of sulfides solidify into towering chimneys as tall as a three-story house. At four hundred degrees this scolding cocktail of chemicals would be lethally toxic to most forms of life, but astoundingly, a particular kind of bacteria thrives here”. The words are Sir David Attenborough’s and it is not hard to see why a twelve-year-old Mark Dopson – when hearing the natural historian talk about deep sea hydrothermal vents – decided there and then to pursue a career in science, and in particular dig deep into the depths of extreme microbiology.

Chasing copper

The vast majority of the easily broken down copper minerals in the world have been consumed. The majority of what is left is something called chalcopyrite, which biologically degrades very slowly and very poorly – because of this, you lose a lot of copper when not using high temperatures, which is less environmentally friendly.

To break down chalcopyrite in a more sustainable manner, Mark Dopson and his team is researching and trying to improve bioleaching – a process where you take the mineral-containing rock and stack it in huge piles – kilometers long, kilometers wide and a hundred meters high – and put acid on top. Imagine a coffee filter: You poor some hot water on top of ground beans, it reacts and drinkable coffee trickles down. In bioleaching, you have a big heap of ore, you put acid and microbes on top, it reacts and what comes down at the bottom is a copper containing solution.

The Goldilock’s Zone

Oxidized iron, called ferric iron or Fe3+, breaks down the minerals in these piles. The idea has previously been that because of this, you should just shove a bunch of it in there and the job is done. What Mark Dopson has found is what he calls the Goldilock’s zone.

“You know the story? It can be too hot or too cold or just right. Now, there is a Goldilock’s zone for the oxidation reduction potential in copper bioleaching, not too high, not too low because then you don’t have enough ferric iron, just right”, says Mark Dopson.

Too much oxidized iron creates a solid layer on the surface of the copper mineral, which stops the mineral from breaking down. To keep this in check, microorganisms can be used. Some push the oxidation levels too high, some too low and some keep it just right. Mark Dopson’s research concludes that the bacteria Leptospirillum ferriphilum should be kept out, in contrast to what the majority of bioleachers practice, and the bacteria Sulfobacillus thermosulfidooxidans should be used instead.

“So the goal now is to take that idea, keep Leptospirillum out, keep Sulfobacillus in, and scaling what we did in the lab to pilot industrial scale”, says Mark Dopson.

That is easier said than done, however.

“A heap that is one kilometer long, one kilometer wide and a hundred meters high. How do you control that? It’s relatively easy to do it in a lab, because we’re in small scale controlled conditions, but you can’t do that in the real world”, says Mark Dopson.

So how do you control it? Mark Dopson has a couple of hypotheses, but none he feels like sharing just yet.

“I don’t want to tell all our competitors exactly how we plan to do this. Copper is used in computers, iPhones, batteries, you name it. This is a big industry. They usually get 40-60 percent of the copper out of the heap, if we can increase that to 60-70 percent, that’s a lot of copper”, says Mark Dopson.

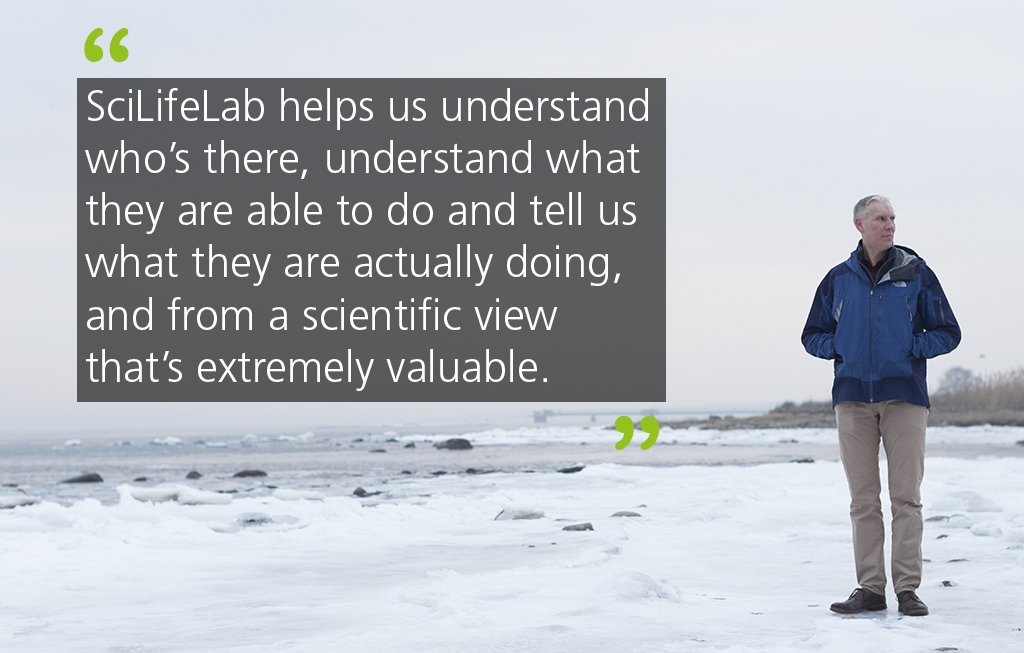

To know which microorganisms could do the job in these different projects a number of methods are used. SciLifeLab helps out with amplicon sequencing (to see what species are present), metagenomics (to see what metabolic processes the microorganisms are able to carry out) and metatranscriptomics (to see what the microorganisms are doing at a particular point in time).

“SciLifeLab helps us understand who’s there, understand what they are able to do and tell us what they are actually doing, and from a scientific view that’s extremely valuable”, says Mark Dopson.

Leading a quiet life

Apart from going back to England for two years for his postdoc, Mark Dopson has lived in Sweden since 1993 when he began his PhD studies in Umeå. So why does one move to, and stay in, a country that is pitch black and covered in snow large parts of the year? For Mark Dopson, the Swedish nature with its mountains, fresh air and clean water convinced him. He also found Sweden to be a good place for raising kids.

“I think the opportunity for everybody to go to university no matter their financial conditions is a huge plus for Sweden, and the quality of education is excellent”, says Mark Dopson.

When asked if he has any personal hopes or dreams, Mark Dopson instinctively answers that he would be happy just being in nature and living a quiet life. But there is one thing that captivates him – he would love to go to Antarctica.

“I’ve thought about taking a sabbatical and finding a research group that are doing interesting work in Antarctica and ask if I can come and visit for a couple of months and help out”, says Mark Dopson.

Environmental benefits

Increasing the efficiency of bioleaching would, apart from being more profitable, also decrease the environmental impact of the method, because the waste that is left has less heavy metals in it, according to Mark Dopson.

Pouring acid on top of a pile of rocks doesn’t sound that environmentally friendly?

“In that sense, no. What we’re trying to do is engineer the heap and the conditions so that we can choose the microorganisms we want. So in that sense, it’s more environmentally friendly than traditional techniques. But don’t get me wrong, you take a finite resource and you’re purifying it, there’s no such thing as sustainable mining, you can only make it as good as you can”, says Mark Dopson.

Another technique for cleaning mining waste waters Mark Dopson is researching, apart from bioleaching, is a biotechnology using what is called “microbial fuel cells”. This technique both cleanses the waste waters from acid producing compounds and produces electricity. You should not stare yourself blind on the potential electricity production though, Mark Dopson points out, the environmental benefits of cleaning the waste is a good thing in itself.

The biobattery

The microbial fuel cell technique, or “the biobattery” as Mark Dopson calls it, could very well sound like science fiction to the uninitiated – electricity is produced by microorganisms. The potential electricity production is currently in the milliamps level, able to power small electrical devices, something that needs to be researched and improved if it is going to be used on a large industrial scale.

“If you get enough electricity to, say, run your pumps, this process doesn’t cost you anything and you’re still gaining environmental benefits. The companies gain clean water that they can potentially recycle back into their process. They also improve their environmental footprint when they’re releasing clean water, which makes regulatory bodies happy with them. So the electricity is not the only benefit, there’s an environmental win there as well”, says Mark Dopson.

This is also a potential financial incentive for companies, most of them are obliged by law to clean their waters. Doing this biologically rather than with purchased chemicals could save them some money.

So, how does this microbial fuel cell technique work exactly? Every organism uses energy. Humans for instance eat food that has chemical energy in the bonds between the different molecules. The mitochondria turns that energy into ATP – the energy of the cells used to power different functions in our bodies. The chemical entity accepting electrons in humans is oxygen, and from that carbon dioxide is produced. Bacteria can, apart from oxygen, use different kinds of electron acceptors, such as nitrate, sulfate, and – what is important here – solid electrodes, or solid anodes, which basically is the terminals where electrical currents flow in from the outside. All options except the solid electrode is removed, which forces the bacteria to produce an electrical current when a cathode – where electrical current flows out – is on the other side. So, in short, bacteria have a bunch of options for producing energy, but only the option that also produce electricity is made available to them – forcing the bacteria to produce electricity by degrading toxic waste.

“We found these microorganisms, we selected them out of the environment, we got them growing and we could generate electricity. At this stage it’s not a huge amount of electricity, it’s something we need to develop and optimize, but it’s electricity, and we’re cleaning the waters”, says Mark Dopson.

The fascination of David Attenborough’s “scolding cocktails of chemicals” really did influence a lifetime of research.

“I don’t quite work on deep sea hydrothermal vents, but I work with extreme biology and that’s what this is: Extreme microbiology”, says Mark Dopson.